Pittsburgh Post-Gazette|post-gazette.com

Much of the wastewater is the byproduct of a drilling process called hydraulic fracturing, or fracking, which pumps at least a million gallons of water per well deep into the earth to break layers of rock and release gas. When the water is sucked back out, it can contain natural toxins dredged up during drilling, including cadmium and benzene, which both carry cancer risks. It also can contain small amounts of chemicals added to enhance drilling.

But DEP officials say one of the most worrisome contaminants in the wastewater is a gritty substance called Total Dissolved Solids, or TDS, a mixture of salt and other minerals found deep underground. Drilling wastewater contains so much TDS that it can be five times as salty as sea water.

Large quantities of TDS can clog machinery and change the color, taste and odor of drinking water -- precisely the problems reported along the Monongahela River. While it's not considered particularly harmful to people, it can damage freshwater streams, which is what happened when TDS levels skyrocketed in Dunkard Creek last month.

Drilling companies currently dispose of their wastewater in Pennsylvania's municipal sewage plants, which then discharge it into rivers and streams.

The U.S. Environmental Protection Agency warns against this because the sewage plants aren't equipped to remove TDS or any of the chemicals the water may contain. Of even more concern, TDS can disrupt the plants' treatment of ordinary sewage by killing organisms that are needed to treat human waste. But the EPA is giving some Pennsylvania plants a permit amendment to accept oil- and gas-drilling wastewater, if they can prove their treatment processes won't be damaged and that the streams they discharge into won't be harmed.

When U.S. Steel and Allegheny Energy complained about the Monongahela River's water in 2008, the DEP found almost twice as much TDS as the agency considers safe. DEP officials blamed some of the problem on the river's low flow last summer and on abandoned mines that have leaked TDS into the river for decades.

What apparently tipped the balance, however, was the drilling wastewater that nine sewage plants were discharging into the river. Only one of those plants had a permit amendment to accept drilling wastewater.

Steve Rhodes, president of the Pennsylvania Oil and Gas Association, an industry trade group, argues that most of the TDS came from abandoned mines, not from drilling wastewater. A study prepared for a different trade group came to the same conclusion.

Mr. Rhodes also said Pennsylvania's waterways "are not anywhere near" their capacity to handle TDS and that the DEP's estimate of how much wastewater the industry produces is "completely exaggerated."

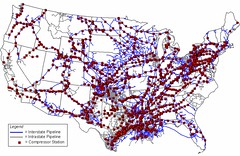

In April, drilling companies began temporarily trucking their wastewater to other states or to sewage treatment plants in other parts of Pennsylvania: The idea is to dilute it by spreading it among more rivers. DEP chief John Hanger said a more permanent solution will begin on Jan. 1, 2011, when new regulations will be in place requiring that the wastewater be treated by plants capable of removing TDS.

Currently, no plant in Pennsylvania has the technology to remove TDS, and it's unlikely that new plants capable of doing so can be built by 2011. Seventeen permit applications for new treatment plants have been filed so far, but the company whose bid is furthest along says its plant won't be ready until at least 2013. And at its peak that plant would be able to treat only 400,000 gallons of wastewater a day. The DEP would need 50 plants that size to process all the wastewater expected by 2011.

In the meantime, the DEP is allowing municipal sewage plants to temporarily continue taking drilling wastewater, even though none of them can remove TDS.

"That's not what these municipal plants are designed to handle -- the DEP is inviting legal problems as well as environmental problems," said Bruce Baizel, a senior attorney for the Oil and Gas Accountability Project, a Colorado-based nonprofit that focuses on the environmental impact of natural gas drilling throughout the United States.

As the DEP's responsibilities grow, its operating budget could be slashed: The state Legislature's latest draft of Pennsylvania's 2010 budget calls for a 25 percent cut in DEP funding.

Mr. Hanger says Pennsylvania's extensive experience with oil drilling has prepared it to deal with gas drilling problems quickly.

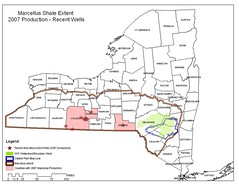

But ProPublica found that the DEP was caught off guard by the amount of wastewater the industry would produce when drilling began in the Marcellus Shale, a deeply buried layer of rock that some analysts say holds enough gas to meet all the nation's natural gas needs for more than 20 years.

When energy prices spiked in 2008, drillers flocked to Pennsylvania, bringing sorely needed revenue and jobs. A recent Pennsylvania State University study touted the benefits drilling brought last year: 29,000 jobs and $240 million in state and local taxes.

Even the industry's wastewater promised profits.

"Cha-ching!" is how Francis Geletko, financial director for the municipal sewage treatment plant in Clairton, described his first thought when he learned that drillers would pay 5 cents a gallon to get their wastewater processed at his plant.

The 1960s-era facility is in such desperate need of modernization that workers still use shovels to remove solid waste from its traps and filters. Many of the state's plants are similarly outdated: A recent report commissioned by Gov. Ed Rendell concluded that Pennsylvania needs to spend $100 billion over the next 20 years to maintain its aging sewage plants and pipelines.

Ed Golanka, who manages the municipal sewage treatment plant in Charleroi, said that when he checked with the DEP nobody told him that state and federal laws required his plant to get an amendment to its permit before accepting industrial wastewater. The amendment would require expensive modifications to allow it to treat industrial wastewater, which Charleroi couldn't afford to do, he said.

"At the time it was a new subject for all of us," Mr. Golanka said. "There was a limited amount of conversation [with the DEP] until the issue with TDS last summer."

Mr. Aunkst, the DEP's director of water standards, said he didn't know the plants along the Monongahela River were accepting the water until the spring of 2008, when people living near the plants complained to the DEP about long lines of trucks idling at sewage treatment plants. But the agency was so short-staffed that it didn't respond to the complaints immediately. Mr. Aunkst said many DEP regulators had left for more lucrative jobs with drilling companies.

"As the industry was ramping up, we were ramping down," he said. "In order for us to really catch these people we have to almost have an inspector coincidentally there on the day that these trucks pull up, because we have so many facilities and so few staff."

...

After Mr. Aunkst heard about the trucks, he wrote a letter to all of the state's sewage plants, reminding them that they couldn't take the wastewater without a special permit.

But before he sent it, TDS levels in the Monongahela River skyrocketed, causing U.S. Steel and Allegheny Energy to complain. The chain of events made Mr. Aunkst remember two other peculiar incidents: Cross Creek and Sugar Run Creek in Washington County were sucked dry, and DEP inspectors suspected that drilling companies had withdrawn the water to fracture nearby wells.

"We were trying to scramble, to put it bluntly, to get our act together to figure out how we were going to address these withdrawals as well as the disposal issues," Mr. Aunkst said.

The DEP did two things to lower the Monongahela's TDS level quickly. It unlocked dams upriver to flush out some of the TDS. And it ordered nearby sewage treatment plants to reduce the amount of drilling wastewater they accepted to just 1 percent of the total amount of water that flowed through their plants each day.

...

Some sewage plant operators were so alarmed that they stopped taking any wastewater at all.

But by January, the uproar had subsided. TDS levels in the Monongahela River were back to normal and plant operators began accepting the wastewater again, although in smaller quantities, as the DEP instructed.

"We didn't want to be the ones to stop the economy from growing in this area, and we felt that we were helping the country become energy independent," said Joe Rost, chief engineer at the municipal sewage treatment plant in McKeesport.

Mr. Hanger has promised to implement more aggressive regulations by 2011 that would require all drilling wastewater to be treated in special plants that are capable of removing TDS, rather than in sewage treatment plants.

...

But spokesmen for eight of the 17 plants that have been proposed told ProPublica it will be impossible to get the plants built by 2011. A spokesman for Larson Design Group, whose application to build a plant in Williamsport, Lycoming County, is furthest along in the process, expects that after it gets its permit, construction will take at least 40 months.

...To read this article in its entirety, CLICK HERE.

Joaquin Sapien is a reporter for ProPublica, a nonprofit journalism organization in New York City. For more on natural-gas drilling, go to http://www.propublica.org.

American Spirit Enterprises Inc. can "remove" better than 95% of ALL TDS's

ReplyDelete