To: New York State Senate Standing Committee on

Environmental Conservation

Room 902 LOB

Albany, New York 12247

From: Wilma Subra

Subra Company

P. O. Box 9813

New Iberia, LA 70562

337 367 2216

subracom@aol.com

September 30, 2009

Subject: Clean Water Hearing

Thank you for the opportunity to submit information for consideration by the New York State Senate Standing Committee on Environmental Conservation as part of your Clean Water Hearing.

Subra Company provides technical assistance to individuals and community groups dealing with a host of environmental issues and situations. I have work with individuals and community organizations on oil field drilling and production operations and the impacts of the operations and generated waste on human health and the environment since the 1970s. I have also served on a number of advisory committees at the local, state and national level dealing with oil and gas drilling and production waste. These advisory committees reviewed the impacts to human health and the environment caused by the waste, developed proposed remedial activities, developed proposed legislation, guidelines and policies, and evaluated specific methods of assessing environmental damage (resume attached).

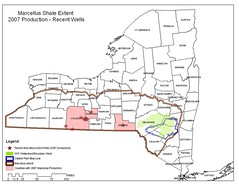

Today in response to the call by the Senate Committee on Clean Water issues, I would like to take this opportunity to focus on availability of water resource and the threat of contamination of water resources by hydraulic fracturing operations in conjunction with the development of natural gas from the Marcellus Shale in New York State.

Protection of Quantities of Surface Water and Groundwater Resources

Hydraulic fracturing in the Marcellus Shale requires large quantities of water. Vertical wells require in excess of one million gallons per fracturing event. Horizontal wells require more the three million gallons of water for each fracturing event. The water resources needed for fracturing come from surface water resources and/or groundwater resources. The use of surface water resources frequently impact the hydrology of the surface water bodies. Depending on the number of wells being fractured in a particular water body segment, the withdrawal of large quantities of surface water could substantially impact the availability of the surface water resources downstream, and damage the aquatic life in the surface water bodies. When groundwater resources are used in the fracturing process, the groundwater aquifers can be drawn down and result in water wells in the area going dry. It is essential when a facility applies for a permit to drill a well in the Marcellus Shale that the regulations require that the permit requirements include identification of the source of hydraulic fracturing water and quantity of water to be used. The regulations must also require that the agencies within the state that have jurisdictions over surface water hydrology/resources and groundwater resources must review the permit information and concur or object to the use of the water resource based on proposed removal of the anticipated quantities of water. Concurrence by the appropriate agencies must insure that the removal of the water will not negatively impact the water resource.

Risk to Surface Water and Ground Water Resources

Hydraulic Fracturing generates a large quantity of flowback water during and following the Hydraulic Fracturing process. The flowback waters contains and are contaminated with fracturing chemicals and fluids that were incorporated into the water prior to the fracturing process. These chemical components include surfactants, friction reducing chemicals, biocides, scale inhibitors and propping agents. The chemicals contained in the flowback water are toxic and are possible and probable human cancer causing agents. The specific chemical compounds that are contained in the additives used in the Hydraulic Fracturing fluids are not publicly available. Material Safety Data Sheets are available for most of the substances used in the fracturing process. However most of the substances listed in the MSDS are described as propriety or trade secrets and are not identified as specific chemicals. There is a desperate need for the specific chemicals in each fracturing material to be identified for use by emergency responders, evaluation of chemical components in chemical spills, identification of specific chemicals causing damage to humans and animals, identification of chemicals in spills into surface water and groundwater resources, and identification of chemicals in drinking water resources. The state of New York should adopt regulations requiring full disclosure of chemicals contained in drilling and fracturing fluids in order to protect and respond to releases of the chemicals into water resources and the environment.

Management and Disposal of Flowback Water

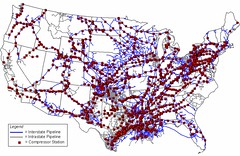

The methods of managing the large quantity of flowback water currently consist of injecting the flowback water into Class II injection wells for disposal and discharge into municipal and industrial waste water treatment plants for ultimate discharge into surface water resources. When a facility applies for a permit to drill a well in the Marcellus Shale, the state regulations should require that the permit application include identification of the methods of managing the waste water and flowback waters from the fracturing process and the locations of the treatment or disposal facilities to be utilized.

The regulatory agencies in the state of New York should evaluate the adequacy of the locations and capacity of treatment and disposal options available for handling waste water and flowback water from Marcellus Shale drilling and production activities. In state as well as out of state facilities and capacities should be evaluated.

The mismanagement of flowback water and produced water can result in negative impacts to surface water and groundwater resources due to spills and leaks on the drilling site, during off site transportation and at the disposal or treatment facility. Inappropriate treatment regulatory requirements or regulatory discharge limitations not covering all of the chemical constituents in the waste water can result in impairment of surface water resources down stream of the treatment facility discharge point.

Frequently the waste water treatment facilities accepting flowback waters do not have sufficient monitoring requirements and effluent limitation in their permits to insure that the chemical components in the flowback waters are required to be treated and removed prior to discharge of the waste water streams. The concentration of chemicals in the flowback water are more concentrated that the normal wastewater stream being treated by the waste water treatment facilities and the resulting effluent from the plants have a very detrimental impact on the receiving waters.

Storage of flowback water and drilling waste water on the drilling site in pits can greatly increase the risk of contamination of groundwater, soils and surface water resources. If unlined or improperly lined pits are used on site to store waste the waste can leach into the soil and groundwater resources under the drill site. In improperly lined pits or pits that have had the integrity of the liner compromised, the waste in the pit can contaminate soil and ground water resources. During closure of the on site pits, if the waste in the pits is not removed and disposed of off site prior to pit closure, the waste can contaminate soil, groundwater and surface water resources. The regulatory agencies in New York should encourage a preference for the use of tanks for storage of waste on the drill site rather than pits and the use of closed-loop systems to reduce of eliminate the quantity of drilling muds and fluids dumped into pits on site. Use of the closed-loop system also reduces the quantity of drilling waste needed to be disposed of after the drilling operations have been completed.

One method to address a number of these issues before drilling occurs is to require a Waste Management plant to be submitted and approved along with the permit to drill A Waste Management plan should require information such as where and how the flowback water, drilling fluids, produced waters and drill cuttings will be managed and disposed of, what specific chemicals will be used in the Hydraulic Fracturing fluids, what methods of storage of waste and produced fluids will be used for storage on site (examples pits, tanks, frac tanks, etc.), what methods will be used to prevent leaks and spills on site, what methods will be used to clean up and remediate the site prior to converting the site to a production facility, and what type of storage will be used for production waste.

Hydraulic Fracturing

In order to further protect groundwater resources, the State of New York should adopt regulations that require the reporting of the horizontal and vertical extent of fracturing to insure that the fracturing activity did not extend fractures outside of the targeted formation. In addition, a requirement for the reporting of the volume of Hydraulic Fracturing fluids remaining in the fractured formation after hydraulic fracturing along with the complete disclosure of chemicals in the fracturing fluids will enable the State to track potential chemicals that may migrate and be detected outside of the fracturing zones.

In order to prevent migration of fracturing fluids out of the designated fracturing formation, a regulatory mechanism should be instituted to identify and evaluate the locations of orphan and abandoned well sites in the area of the proposed wells and in the areas to be fractured. Horizontal fracturing of shale wells can extend out from the well site for long distances and have the potential to intercept orphaned and abandoned well bores. The importance of such measures is to protect ground water resources.

The regulatory process should include requirements that insure that the well piping is able to withstand the pressures to be exerted by the fracturing process and the well construction and completion standards are adequate to protect ground and surface water resources.

Habitat Destruction

The location of well pads and tank batteries are often sited with little or no consideration for the surface uses of the land. Well pads are constructed adjacent to homes, churches, parks, wetlands, and unique environmental areas. Once the habitat on the surface is destroyed by the well pad or tank battery, it is nearly impossible to restore the area to pre existing conditions.

Buffer Zones and Set Back Requirements

In order to protect surface water resources as well as reduce human health impacts, buffer zones and set back requirements should be established by the state regulatory agencies for the location of well sites, storage tank batteries, compressors, and injection well sites, from water bodies, wetlands, unique environmental areas, aquifer recharge zones as well as homes, buildings, schools, churches, and parks.

Air Emissions

The call for this hearing was clean water, however air emissions frequently result in deposition of toxic chemicals into water bodies which result in impacts to water quality and the aquatic environment.

Natural gas condensate is produced with natural gas. The condensates contain extremely toxic volatile organic compounds such as benzene (a known human cancer causing agent), xylene, toluene, ethylbenzene and other probable and possible cancer causing agents. These toxic chemicals are releases into the air from the gas separation process and tank storage of condensates. Produced water stored in tanks release methane, toxic volatile organic chemicals and sulfur based compounds into the air. Compressors and diesel fueled motors release combustion products into the air. These products combine with the volatile organic chemicals in the presence of heat and sunlight to form ozone. Elevated ozone levels result in increased respiratory impacts for community member in the area. Even though the call for this hearing is clean water, the potential for air emissions to negatively impact water quality is an important issue that must be considered.

Regulations and Enforcement

The citizens of the state of New York are in need of strong, regulatory programs to safe guard the water resources of the state from the detrimental impacts of Hydraulic Fracturing and shale gas drilling and production. Historically regulatory programs lacked adequate requirements to protect the environment and human health. Community members have suffered too long as a result of inadequate regulations and the lack of enforcement of existing regulations. The regulatory agencies frequently state they do not have adequate resources to enforce the existing regulations.

With the hugh focus on drilling and production of shale gas in the Marcellus Shale, the regulatory agencies in the State of New York need to be provided with adequate resources and staff to review, evaluate, and issue appropriate permits for shale gas wells. The agencies also need sufficient resources and staff to observe field activities during drilling and fracturing processes, perform compliance monitoring, respond to citizens complaints and enforce the regulations in order to protect water resources and human health. For too long the aquatic environment and community members have suffered due to the lack of regulations and the lack of enforcement of existing regulations.

Now is the time to enact strong regulations and ensure enforcement of those regulations for shale gas drilling and production and hydraulic fracturing in order to insure that these activities do not destroy and contaminate surface and groundwater resources, human health and the environment.

Nice ste please viast mine filled with facts..

ReplyDeletehttp://push.pickensplan.com/group/natualgasfacts#

delhi/india based manufacturer and supplier of hospital/medical furniture and provide laboratory furniture, lab furniture, hydraulic tables, Semi- Fowler Bed, Baby Cots, hospital beds (electric hospital bed), Dressing Trolley, Instrument Trolley etc.

ReplyDeleteReally no matter if someone doesn't know after that its up to other visitors that they will help, so here it happens.

ReplyDeleteAlso visit my web blog; diets that work fast for women

Superb! I love it. Obviously the way you test them depends on the extent of your own knowledge. You can't ask them a question you don't understand yourself! Doing a bit of internet research and relating it back to your equipment or a problem on your site should be sufficient. thanks!~ Leslie Young

ReplyDeleteGreat detailed information, I ll be visiting you more frequently, here is very interesting information.

ReplyDeleteOzone Waste Water Treatment & Ozone Generators

I love to read your post now m waiting for next post

ReplyDeletehospital furnitures

Thanks

ReplyDeleteThis blog is truly useful to convey overhauled instructive undertakings over web which is truly examination. I discovered one fruitful case of this truth through this blog. I will utilize such data now.

ReplyDeleteHospital bed repair

Hii great reading your blog

ReplyDeleteسایت شرطبندی شیر بت با ارائه بازیهای متنوع کازینویی و پیشبینی ورزشی، فضایی مطمئن و حرفهای برای علاقهمندان به شرطبندی فراهم کرده است. این سایت با رابط کاربری آسان، درگاههای امن و واریزهای سریع، تجربهای جذاب را برای کاربران رقم میزند. همچنین با بونوسهای ویژه و ضرایب بالا، شانس برد کاربران را افزایش میدهد.

ReplyDelete