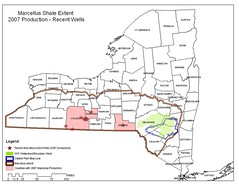

The Marcellus Shale Coalition issued the following statement Feb. 4 regarding water use and flowback water management in the development of natural gas from the Marcellus formation:

“Pennsylvanians deserve to get the facts about water management for Marcellus shale development. We need to put an end to the suppositions that could threaten our state’s ability to create jobs and investment here at home.

“Regulations governing the use and management of water needed to drill a Marcellus shale well in Pennsylvania are among the most stringent in the nation, (But that doesn't mean they are stringent enough!) and ensure the protection of the commonwealth’s water resources. (Though to date they haven't always done that.) Water withdrawals from streams and rivers must be approved, including the withdrawal location and amount of water required for each well, as well as detailed storage and treatment plans. (This does not guarantee protection either.)

“The industry currently treats or recycles all of its flowback water. Recycling accounts for approximately 60 percent of the water used to complete Marcellus shale wells, with greater percentages predicted for the future. There are more than a dozen approved water treatment facilities available to treat flowback water, with plans for additional capacity in the future. (Recycling recoverable water does not preclude or prevent pollution from the toxic fracking fluid that remains in the well bore. Flowback accounts for only a fractional percent of the water used in drilling in the Marcellus shale. CLICK HERE for a .pdf file of PA wastewater facilities.)

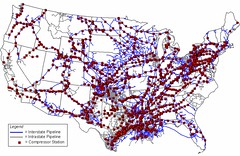

“Companies are working with international water quality experts and are funding research and development projects to develop mobile and permanent treatment technologies such as evaporation and crystallization. These efforts will enhance the commonwealth’s overall water treatment capabilities, while bringing more commerce into Pennsylvania. We’re also researching and developing deep underground injection well technology, which is a proven, safe disposal method in other regions of the country. (But not a proven, safe disposal method for our geology. Here wastewater returns to our watershed. ...And, as fracking chemicals remain an industry secret, how can we know we've safely "treated" produced water for reintroduction into our enviroment?)

“Claims about elevated levels of Total Dissolved Solids (TDS) in the Monongahela River from natural gas development have been refuted by studies that attribute a minimal amount of the total TDS levels to Marcellus shale drilling activity. In fact, historical monitoring shows the variability of TDS levels in the Monongahela and other rivers to be a cyclical phenomenon over the past 30 years. (Smoke and Mirrors!) Convincing arguments may not be provable beyond doubt, but the possibility of contamination could be avoided if proper wastewater treatment facilities were in place BEFORE more drilling is permitted!

On Feb. 2, 2010, Dave Badger of Treasure Lake, Dubois wrote, in the Tri-County Courier Express: Millions of gallons of gas drilling wastewater are being produced every day and our state doesn't have a single treatment facility capable of properly treating it. Currently, much of the wastewater is being trucked to some municipal sewage and industrial treatment plants across the state where it's haphazardly treated before being discharged into our rivers and streams. These treatment plants are not equipped to remove TDS (total dissolved solids) and other chemical contaminants commonly found in drilling wastewater. High levels of TDS in mining wastewater contaminated Dunkard Creek last September in southern Pennsylvania and northern West Virginia. The salts in TDS caused a golden algae bloom, an algae not known to the region that thrives in brackish water, that wiped out virtually every fish and other aquatic organism along a 30-mile stretch of stream. An estimate of the loss of life was $30 million. Wouldn't it make more sense to have proper wastewater treatment facilities in place before issuing any more drilling permits? Fresh, clean water is our most precious natural resource, not natural gas. Our elected officials are allowing greed to trump common sense.“The industry is committed to the use of Best Management Practices in all aspects of its operations, including significant investment in advanced flowback water treatment capabilities and recycling technologies.”

The Marcellus Shale Coalition is comprised of dozens of drilling and service companies who work in Pennsylvania’s oil and gas industry. Its Web site is www.pamarcellus.com.

The Marcellus Shale Coalition is comprised of dozens of drilling and service companies who work in Pennsylvania’s oil and gas industry. Its Web site is www.pamarcellus.com.LINK

Editorial comments by Splashdown in red.

Thank you for sharing. Cost-effective solutions for flowback water treatment and produced water treatment will play and important role in the economics and environmental sustainability of unconventional oil and gas production.

ReplyDelete